Date April 23, 2024 | Brooke Loeffler

How to Store Leftover Ice Melt Products

Safety Data Sheets (SDS)

First, it is important to stay informed about any industrial product you are using or storing. Make sure the necessary safety data sheets (or material safety data sheets) are easily accessible to all personnel.

- Don’t just rely on digital copies of SDS in case of tech difficulties...keep hard copies on hand as well.

Liquids vs. Solids

Solid products are generally more stable in storage than liquids. Liquid deicers can experience temperature caused decomposition and will have stricter storage requirements than solid ice melt products.

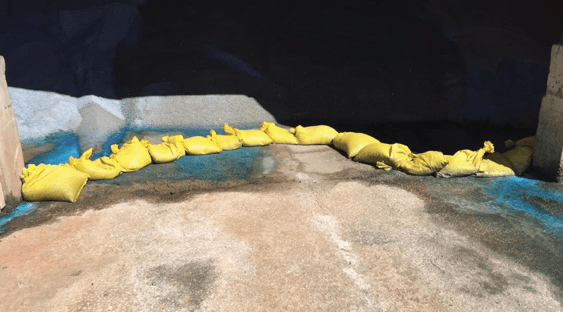

Leaching

Some solid deicers contain dyes and other liquid additives that can leach out during storage.

These products will likely have decreased performance if they are stored for too long. Leaching liquid chemicals can also damage concrete slabs on which they are stored.

Agricultural Byproducts

Some deicers contain agricultural byproducts that contain carbohydrates (from beets, corn, etc.) and are more sensitive than inorganic solids like salt.

- Protect these products from spoilage, pests, and mold growth.

Organization

Using the information in your SDS, come up with an organization plan that stores your leftover product according to the manufacturer’s specifications.

- Store older products in a location where it can be used first before new products.

- Sweep up and collect loose granules that have been spread or dropped around the shed while loading vehicles.

- Unopened packages should be stored flat in a dry area

Once you are organized, you can take inventory and prepare to fill your shed for next winter.

Moisture Management

Moisture and higher temperatures can reduce the shelf life of some leftover deicing products. If your shed does not have access to interior storage, take precautions for products stored outside.

- For 3 sided sheds, divert runoff away from piled product to prevent rainwater seepage.

- Properly cover and seal moisture sensitive products with a waterproof covering

- Remember, salt is hygroscopic and will draw in moisture from the surrounding air. As a result, some salt based deicers may develop an exterior crust over the course of the summer. These clumps can be broken apart before you resume use.

- Repackage, reseal, or cover packages that have been torn or damaged.

Temperature Management

Carefully note the recommended temperature ranges for all products you are storing. Protecting products from temperature extremes will always extend their shelf life.

- Keep products in a location where they will experience as little temperature variation as possible.

- Provide sun protection for liquid deicer products stored in IBC totes

Stable Storage With Ice Slicer®

If your leftover deicer stockpile looks like the product on the left, try stockpiling Ice Slicer next season! Don't waste money on products that lose performance during storage. As an all natural, mineral product, Ice Slicer doesn't degrade or lose any efficiency while you are waiting for the snow to start flying.

One of the many benefits of working with Ice Slicer® is the storage simplicity. Our all-natural ice melt is extremely stable in storage, so you can enjoy the same high performance from left-over product as you can from fresh shipments.

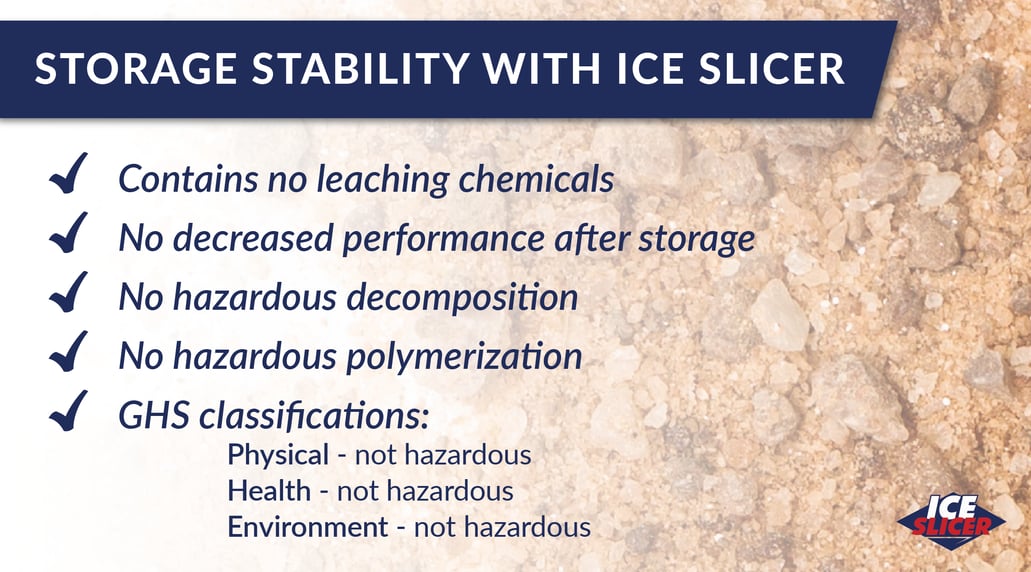

There are many advantages to working with Ice Slicer®:

- Contains no leaching chemicals

- No decreased performance after storage

- No hazardous decomposition

- No hazardous polymerization

- GHS Classifications: physical (not hazardous), health (not hazardous), environment (not hazardous)

Ice Slicer® is proud to support our snowfighting teams on site and out in the field. We can keep your stockpile full and solve your supply chain woes!

Contact us today to see how we can help your operation all the way through the off-season!

© 2024 Redmond Minerals Inc.