Date October 11, 2025 | Brooke Loeffler

How to Use the Right Amount of Deicer

Why Deicer Application Rates Matter

No day or storm are exactly the same, so fine tuning application rates should be an ongoing process. Using the right amount of deicer gives you optimal performance, savings, and a cleaner roadside environment.

Performance

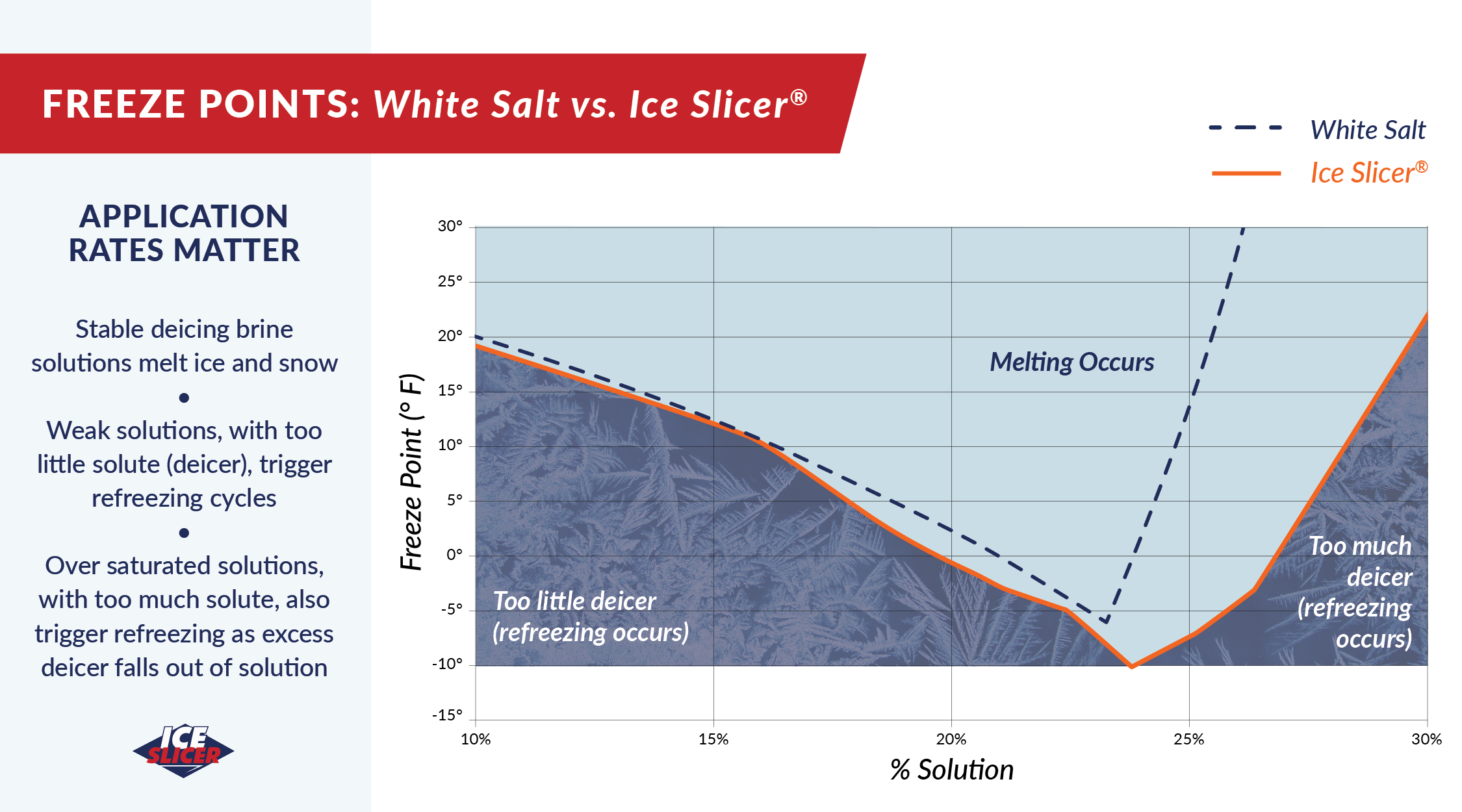

Deicer products have a performance range in which they successfully create brine to melt ice and snow. This brine is a chemical solution that contains: a solute (solid deicer) dissolved in a solvent (water).

- Weak solutions trigger refreezing: not enough solute, too much solvent

- Over saturated solutions also trigger refreezing: too much solute which falls out of solution

Understanding the eutectic temperatures of your chosen product will help you find its peak performance range.

Economy

Paying careful attention to your application rates protects your budget in a lot of ways.

- Prevents over application and product waste.

- Cuts back the need for additional passes: lower fuel costs, less wear and tear on vehicles, etc.

- Improves your ability to manage stockpiles: helps you plan out your season more efficiently to avoid rush and emergency ordering and keep your crews running.

Teams typically purchase products based on cost per ton. However, cost per storm or cost per lane mile more accurately reflect the value of a deicing product. After a storm, evaluate how many lane miles you reached to see if either your purchase choices or your application rates need to be adjusted.

Environment

Everything applied to road surfaces enters the environment to some extent. However, it is possible to balance public safety with environmental responsibility while maintaining winter roads. It is important to remember:

- Overapplying deicer increases the amount of chlorides running off into the soil and attracts more grazing animals to the roadside.

- Over and underapplying deicer can trigger refreezing, causing accidents which are also harmful to the environment

How to Use the Right Amount of Deicer

Proper deicer application starts with a baseline average rate that can be adjusted based on a storm and traffic conditions.

First, Calibrate Your Equipment

Make sure spreading equipment is calibrated to disperse deicer evenly and at the preferred rate per lane mile.

- Click for a snow plow calibrating tutorial video from Ice Slicer®

Check calibration regularly so you don’t waste valuable product.

Follow Supplier Recommendations

Check with your deicer supplier for their recommended application rates and remember that further fine tuning is necessary.

Ice Slicer® application rates typically start around 150-200 pounds per lane mile, but can be increased or decreased as needed.

When To Increase Application Rates

Deicer application rates can be increased under the following conditions:

- During times of heavy traffic flow: According to the Minnesota Department of Transportation "brine is spread more by traffic spray and snowplow throw than by storm runoff." Normal vehicle traffic can initially help break down ice and snow and help with the brining process, but reaches a point of diminishing returns as brine is wicked away more quickly under heavier traffic

- Lower temperatures

- Higher precipitation

- When road surfaces still have stubborn, leftover ice and bare pavement has not been achieved

When to Decrease Application Rates

Deicer application rates can be decreased under the following conditions:

- During times of very light traffic flow

- Higher temperatures

- Lower precipitation

- A lot of excess product is left on road surface after bare pavement has been achieved

More Snowfighting Tools From Ice Slicer®

Ice Slicer® is proud to partner with road management teams across the country to keep drivers safe all winter long. In addition to our all natural, Complex Chloride™ deicer, we also provide other tools for success to help crews get the job done.

Click on the links below for more resources for your shed:

- How to choose a product based on storm conditions

- Snow plow route optimization

- What to do with leftover road treatments

- Frequently Asked Questions about pre-wetting deicer products

© 2024 Redmond Minerals Inc.