Date March 27, 2024 | Brooke Loeffler

Cleaning Up Road Aggregates After Winter: What's The Cost?

Why Do Aggregates Need To Be Cleaned Up?

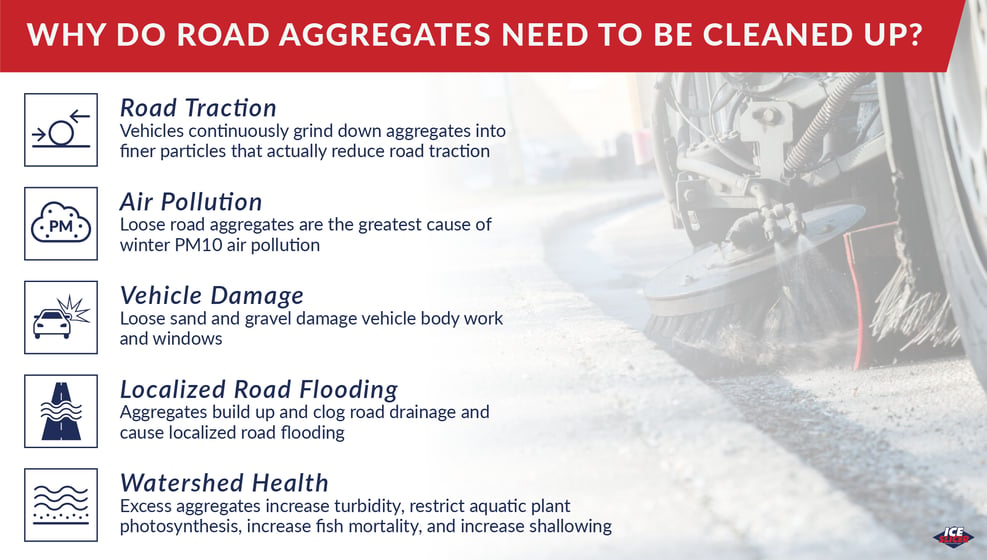

Sand and gravel are substances naturally found on a roadside...so why do they need to be cleaned up at all? There are several reasons these abrasives cannot remain on a roadway.

Traction: The Point of Diminishing Returns

Particles must be a certain size in order to provide effective amounts of traction. As these aggregates remain on the road, vehicles grind them into finer and finer particles. This finely ground sand does not create sufficient traction coverage. In fact, it can cause dangerously slippery conditions as these abrasives break down. The Colorado Department of Transportation conducted a study on the effect of road sand aggregates in Denver and found that:

“leftover sand on the streets decreases the coefficient of friction which causes skidding and stopping distances to increase. This poses a threat to drivers and increases the probability for accidents.”

Air Pollution

As vehicles drive over loose aggregates, they are crushed by traffic and create airborne dust or particulate matter (PM). These particles continue to disperse and build in a city’s airshed and create hazardous breathing conditions. There are many locations across the snow belt in the United States that struggle to meet federal clean air standards because of PM pollution (both PM 2.5 and PM 10) from road aggregates.

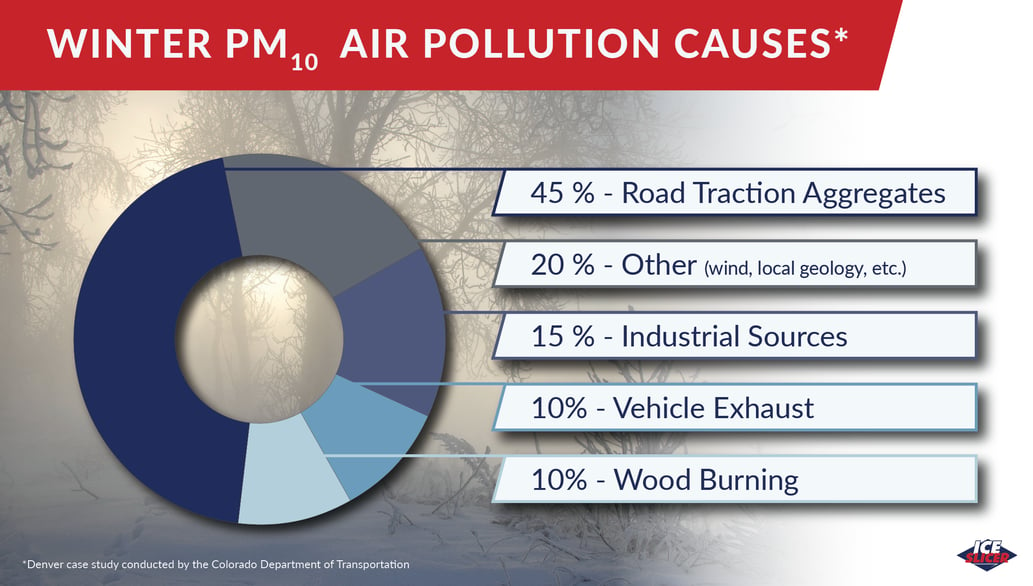

In the same study mentioned above, the Colorado Department of Transportation found that road sand is the greatest contributor to a city’s PM10 pollution levels.

A Breakdown of winter PM10 air pollution causes:

- 45% - Road Aggregates

- 20% - Other (wind and other meteorological forces, local geology)

- 15% - Industrial Sources

- 10% - Vehicle Exhaust

- 10% - Wood Burning

This data is further backed up by the American Association of State Highway and Transportation Officials (AASHTO) that found that:

“Vehicle grinding of sand allows fine particulate matter, PM10 (or PM2.5), to become airborne when dry...sand used for snow and ice control increases air pollution and has been estimated to contribute approximately 45 percent of the small particulates present in air.”

Vehicle Damage

Excess non-soluble aggregates on the road surface increase dings, scratches, and broken windows on vehicles. Because these additives do not melt, they continue to build up and create unsafe driving conditions with each application. Watch below to see which is safer around cars...gravel or Ice Slicer®

Localized Flooding

Road abrasives accumulate over the winter and clog catch basins, storm water inlets, and drainage pipes. These blockages lead to localized flooding, road closures, costly pumping, and avoidable infrastructure repairs.

Waterway Health

AASHTO has tracked the negative effects of road sand on water quality as well, especially during the spring run-off. They stated:

“there have been studies by ecological experts that have concluded that the detrimental environmental effects of sand generally outweigh those of ice melting chemicals.”

Road aggregates are very harmful to waterways, as they:

- Wash into local waterways and increase turbidity (murky cloudiness)

- Reduce photosynthesis for aquatic plants

- Increase mortality in fish

- Contribute to the unnatural shallowing of waterways

Learn more from our partners at EnviroTech Services the disadvantages of using sand for road traction.

Cleaning up Road Aggregates

Now that we have seen why road aggregates must be cleaned up, let’s take a look at the clean up process itself.

Equipment

It takes more than a single pass from a street sweeper to remove excess road aggregates. Multiple pieces of equipment and multiple passes are needed to pre-wet (to reduce air pollution), consolidate, and remove these abrasives.

Watch the video below showing how many passes it takes to remove non-soluble aggregates from a single street in Sweden.

There are many different types of cleaning equipment used. For a comprehensive list of equipment types and their efficiency rates visit the Federal Highway Administration (FHWA). The FHWA estimates that for

“a heavy duty mechanical sweeper, and coverage of 2 or 3 miles a day at a price of $300 a road mile is in the ballpark.”

And the use of a “regenerative air sweeper (more thorough cleaning of all particle sizes over the road surface). The cost of regenerative air sweepers may be 2 to 2.5 times the cost of a traditional sweeper.”

Financial Costs

When you compare road aggregates to granular deicers, upfront costs appear to favor aggregates. However, factoring in sand and gravel’s inability to melt ice and snow, and the post winter clean up costs...granular deicers are considerably less expensive.

In 2001, Swiss researchers Ulrich Schlup and Beatrice Ruess conducted a well respected study comparing road abrasives and salt. Federal, state, and local governments use their findings to help them better weigh the financial and environmental costs of using abrasives compared to salt. Citing Schlup and Ruess, the Idaho Transportation Department stated that compared to road salt:

“abrasives were more expensive (six times higher in normal winters) and delivered less benefit.”

Environmental Costs

Road cleaning efforts do not sufficiently remove excess aggregates from the environment after the winter. According to AASHTO:

“An Oregon DOT study found that 50 to 90 percent of sand applied to pavements remains in the environment after cleanup.”

This is especially true for snow belt areas where road cleaning efforts have to be put on hold for months at a time.

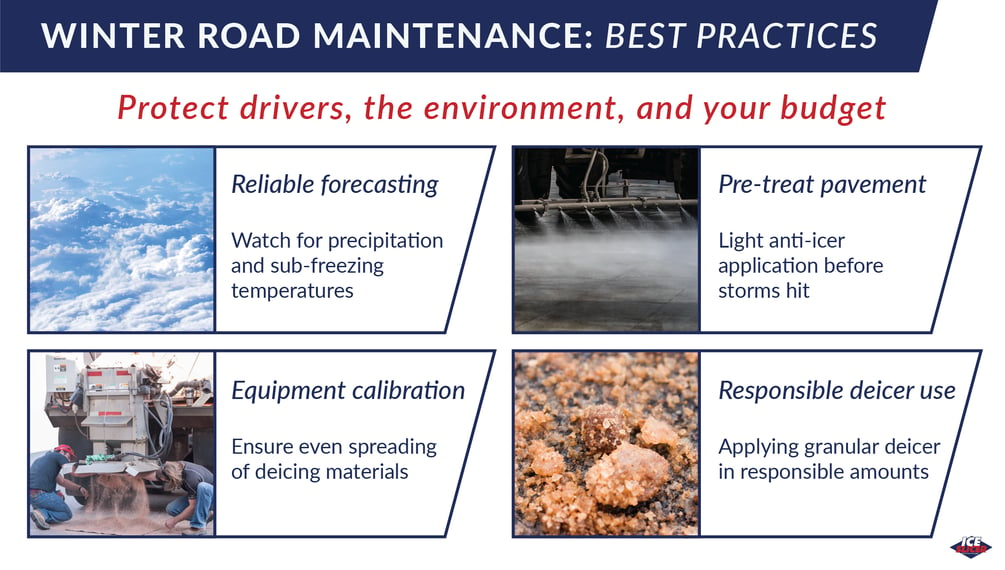

Avoid Additional Aggregates: The Goal of Bare Pavement

Cities in and out of the snowbelt have found that switching from traction sand/gravel to granular deicers saves money, restores road safety, reduces cleanup, and protects airshed and watershed health. It is our duty to look at the big picture in order to make sure we are employing the most responsible winter road maintenance practices.

To protect drivers, the environment, and your budget, use a combination of these best practices:

- Reliable weather forecasting (anticipate precipitation and sub-freezing temperatures)

- Pre-treatment for paved surfaces (light application before a storm)

- Calibration of equipment (make sure your equipment is spreading correctly)

- Responsible use of granular deicers (avoid over-using deicers to protect infrastructure and the environment)

These best practices result in more efficient, cost effective, and environmentally responsible winter road maintenance. Ice Slicer® is committed to helping communities across the continent restore their winter roads to safe and drive-able conditions.

© 2024 Redmond Minerals Inc.