Date January 23, 2024 | Brooke Loeffler

Road Condition Sensors

What Are Road Surface Condition Sensors?

Road condition sensors are a helpful tool in areas that frequently experience ice and snow. They allow snow crews to get more accurate readings of roadway conditions, such as differences between air temperature and pavement temperature. This data helps snow-fighters execute a more targeted approach to each storm, and use their resources more wisely.

Different road surface sensors can monitor:

- Moisture levels

- Coefficient of friction

- Type of precipitation (rain, snow, sleet, hail)

- Pavement temperature

- Wind speeds and direction, and more

Road Weather Information System (RWIS)

RWIS is a centralized hub where private sensor suppliers can send this road data. Here, it is combined with atmospheric data to calculate “nowcasts” and forecasts of driving conditions for a certain area. This information can be extremely useful to road management agencies, and help crews:

- Optimize snowfighting routes

- Anticipate unsafe road conditions

- Know when to apply anti-icing treatments

- Choose the right deicing product for storm and road conditions

- Mobilize the correct number of fleet vehicles

- Dispatch snow fighting teams in a timely manner

- Target most affected areas first

Different Types of Road Surface Sensors

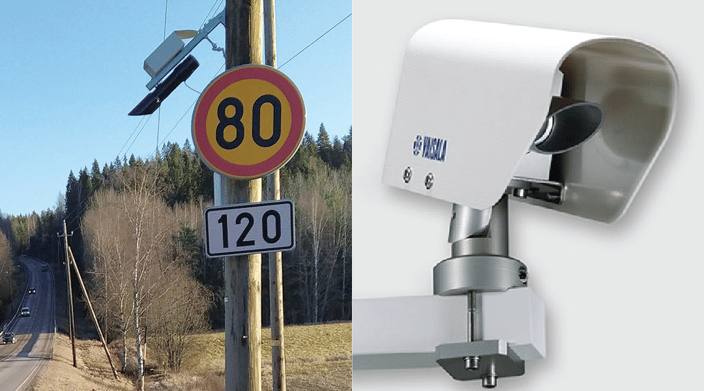

Road-side Infrared Sensors

These roadside devices use infrared technology to detect conditions on paved surfaces within their scope. They are typically placed to target bridges, or other known micro-climate problem areas.

*Photos courtesy of Teconer.fi (left), Vaisala.com (right)

Mobile/Handheld Temperature Sensors

Some organizations use handheld or mounted sensors on fleet vehicles so they can cover more ground. This approach is sometimes used to see how conditions vary across certain areas and identify vulnerable spots for re-calibrating snow fighting efforts.

In Pavement / Embedded Sensors

A new piece of road surface tech has emerged over the last few years, using sensors placed within the pavement itself. These embedded devices give crews highly accurate surface condition readings that help ID problem areas, which can be especially useful during freezing rain events. Eric Faulkner, from Wx Horizon, illustrates some of the benefits in-pavement sensors can provide in the field:

- "Handhelds aren’t as accurate. For example, if they are sitting in a warm area (plow truck) and you bring them out to take the temperature immediately , they will give a false reading until the device cools down. The in-ground sensors are also flush with the surface, so they are going to produce a more accurate reading.

- For handhelds, you need to get out and manually scan the road to measure temperature. With in-ground, you can view the data on your computer or phone through the user interface without having to travel to the location.

- [In pavement sensors] report more variables – handhelds only do temperature of the surface. Our GroundCast sensors record temperature at the surface and sub-surface, state of the pavement (wet or dry), and amount of salt that’s on the roadway.

- Ability to obtain a “thermal profile” and a detailed overview of the road network with multiple stationary sensors.

- Data feeds into a forecast to provide a more accurate, localized forecast on the road.

- Wireless, maintenance-free, and cost-effective – can be installed in most locations.”

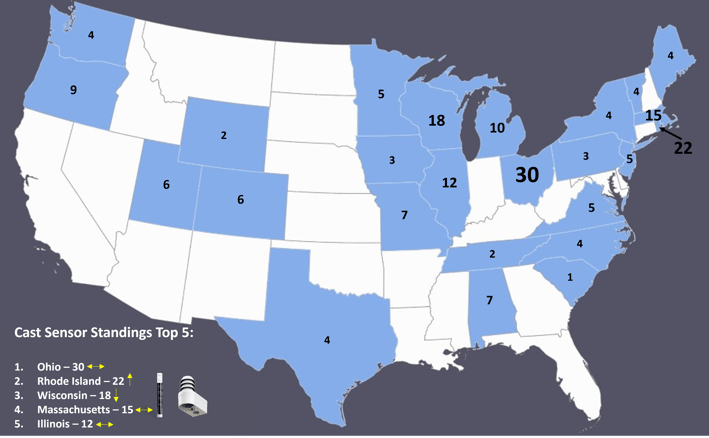

Many states are enjoying the benefits of these new embedded pavement sensors, including these states using cast sensors from Wx Horizon:

*Graphic courtesy of Wx Horizon

*Graphic courtesy of Wx Horizon

Safety and Financial Benefits of Road Sensors

Using sensors to calculate road friction levels is not only important for public safety, it can save municipalities a lot of money. Over-applying deicing treatments wastes resources, stretches personnel hours, and can also put unnecessary strain on the environment. Road surface sensors help teams target ice and snow instead of broadly applying the same deicing strategy to an entire area.

The Colorado Department of Transportation (CDOT) discovered that using sensors to calculate road friction saved them $180,000 in a single winter!

• Read more about how road sensors saved lives and money for CDOT.

Ice Slicer’s® Road Sensor Partnerships

Ice Slicer® is proud to partner with snow fighters and road safety organizations to save lives, and give teams the best deicing tools possible. We are teaming up with Montana State University, The Western Transportation Institute, and the Utah Department of Transportation to take road friction testing even further.

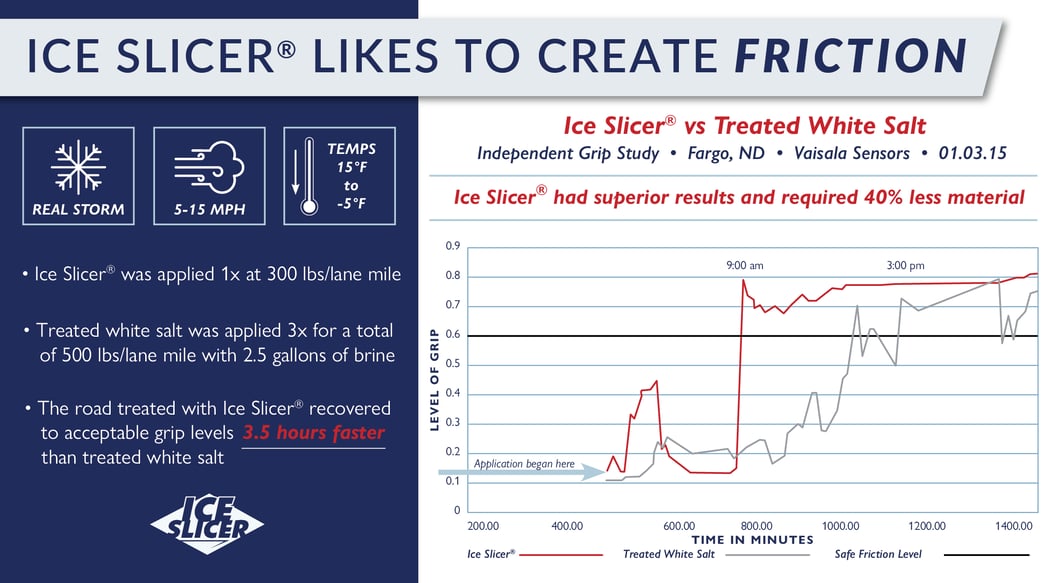

Using fixed and mobile vaisala sensors, we help teams conduct real-world tests on road surfaces to provide side by side comparisons for different road treatment products. These tests show organizations how products perform under their local weather conditions instead of just in a lab.

Here is an example of a real world, side by side friction test conducted in Fargo, North Dakota.

As you can see, this test was conducted under natural winter storm conditions. Ice Slicer's® high performance returned Fargo’s roads to safe traction levels 3.5 hours faster than treated white road salt, and with 40% less product!

© 2024 Redmond Minerals Inc.